Analytics

As we move towards a more sustainable future, optimizing our electric consumption is becoming increasingly important. Not only can it help to reduce our impact on the environment, but it can also help to save money on electricity bills.

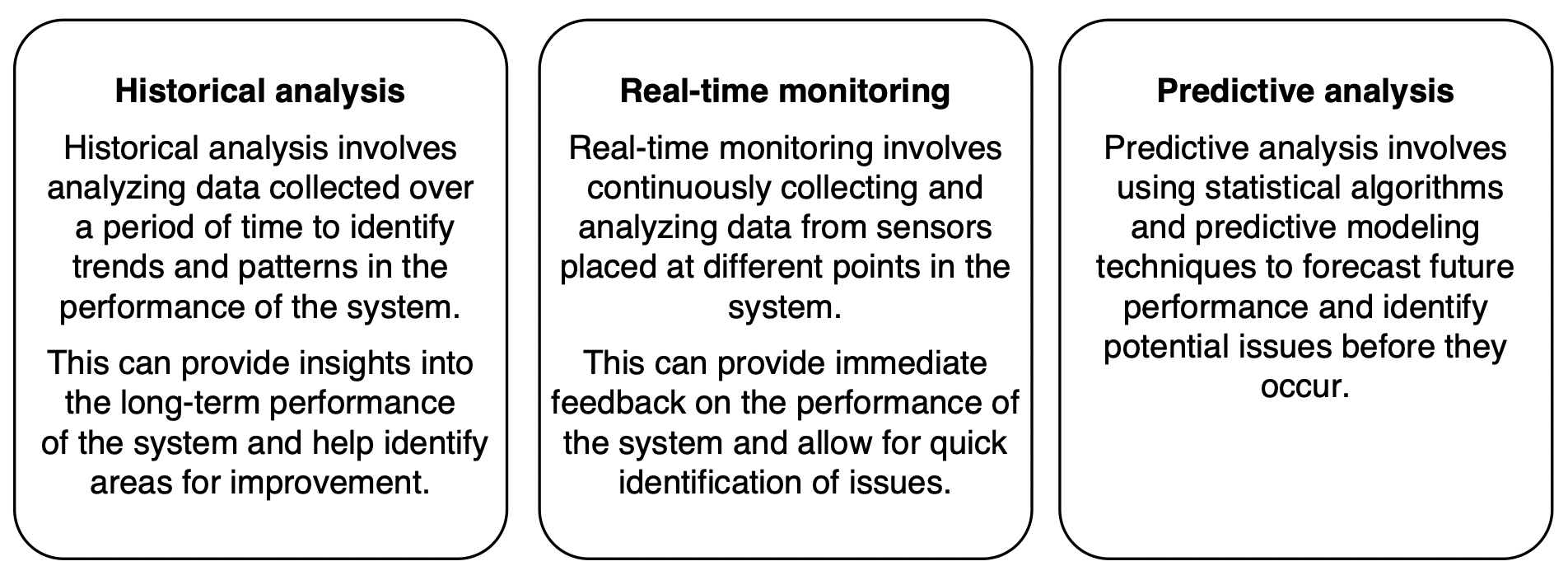

Electrical measurement analysis is a process of collecting and analyzing data related to electrical parameters such as voltage, current, power, and energy consumption. This data can be used to monitor and optimize the performance of electrical systems, identify potential issues, and improve efficiency.

Descriptive statistics deals with the summary and presentation of data in a meaningful way. It includes methods for summarizing and describing the features of a set of data, such as measures of central tendency, measures of variability, and graphical representations. Buildlink BMC examples: Mean, Median, Sum, Standard deviation, Variance, Etc.

Inferential statistics tests a hypothesis or assess whether data is generalizable to the broader population. It is used to describe the characteristics of a known sample or sample-set. Measures of inferential statistics are t-test, z test, clusterin, linear regression, etc. In the context of Buildlink BMC services inferential statistics are custom client solutions.

From basics to advanced analytics

Harnessing the synergy of artificial intelligence (AI) and machine learning (ML) is revolutionizing how we measure electric consumption. These technologies bring data-driven precision, enabling a leap beyond traditional methods.

ML’s predictive analytics optimizes energy use, offering insights into patterns and facilitating real-time anomaly detection. Personalized energy management becomes possible through AI, empowering consumers with tailored conservation strategies. Grid optimization, energy theft prevention and seamless integration with smart devices mark the transformative impact of AI and ML on electric consumption measurement.

As we mark long period into this technological journey, the future promises even more efficiency, security and sustainability in energy management.

Who will use the data and for what purpose?

Within industrial organizations, data from electricity consumption measurement in plants, facilities, and devices serve a multitude of crucial purposes. Engineers and plant managers utilize this data to identify energy-intensive processes and equipment, enabling them to optimize operations and improve overall efficiency. Maintenance teams rely on the information for predictive maintenance, preventing costly breakdowns and ensuring the continuous functioning of equipment.

Financial departments analyze electricity consumption data to manage costs effectively, creating budgets and forecasting expenses related to energy usage. Sustainability and environmental teams use the data to monitor the organization’s carbon footprint, enabling them to implement green initiatives and meet environmental compliance standards.

Furthermore, production planners leverage electricity consumption data to schedule manufacturing processes during periods of lower energy demand, reducing operational costs. Health and safety teams utilize the data to ensure that electrical systems are operating within safe parameters, mitigating the risks of electrical failures and accidents.

In essence, within industrial organizations, electricity consumption data serves as a foundational tool for optimizing processes, managing costs, ensuring safety, and driving sustainability initiatives, leading to more efficient, cost-effective, and environmentally responsible operations.

Electrical measurement analysis and optimization activities offers several benefits:

- Improved efficiency: By monitoring and analyzing energy consumption data, businesses can identify areas of inefficiency and implement targeted improvements to reduce energy waste and improve overall efficiency.

- Cost savings: By optimizing energy usage and reducing waste, businesses can save on energy costs and improve their bottom line.

- Sustainability: By reducing energy consumption and waste, businesses can support their sustainability goals and reduce their environmental impact.

- Maintenance optimization: By identifying potential issues early on, businesses can optimize their maintenance schedules and reduce downtime.